Most ecommerce businesses have long been content with riding the ecommerce wave and resell existing articles that they find on websites like Alibaba.

Now this strategy is quickly becoming too competitive, and for success companies need to differentiate themselves in meaningful ways through the products they sell.

In this video I discuss “Design For Manufacturing” aka. DFM. We will go through how to work with engineers to prepare your product concept for manufacturing.

The latest video is on how to test if a product concept resonates with your target customer. I see many first time entrepreneurs rush this step because they already feel confident that people will love their product. However cutting corners on concept validation is a huge mistake and will likely lead to a lot of…

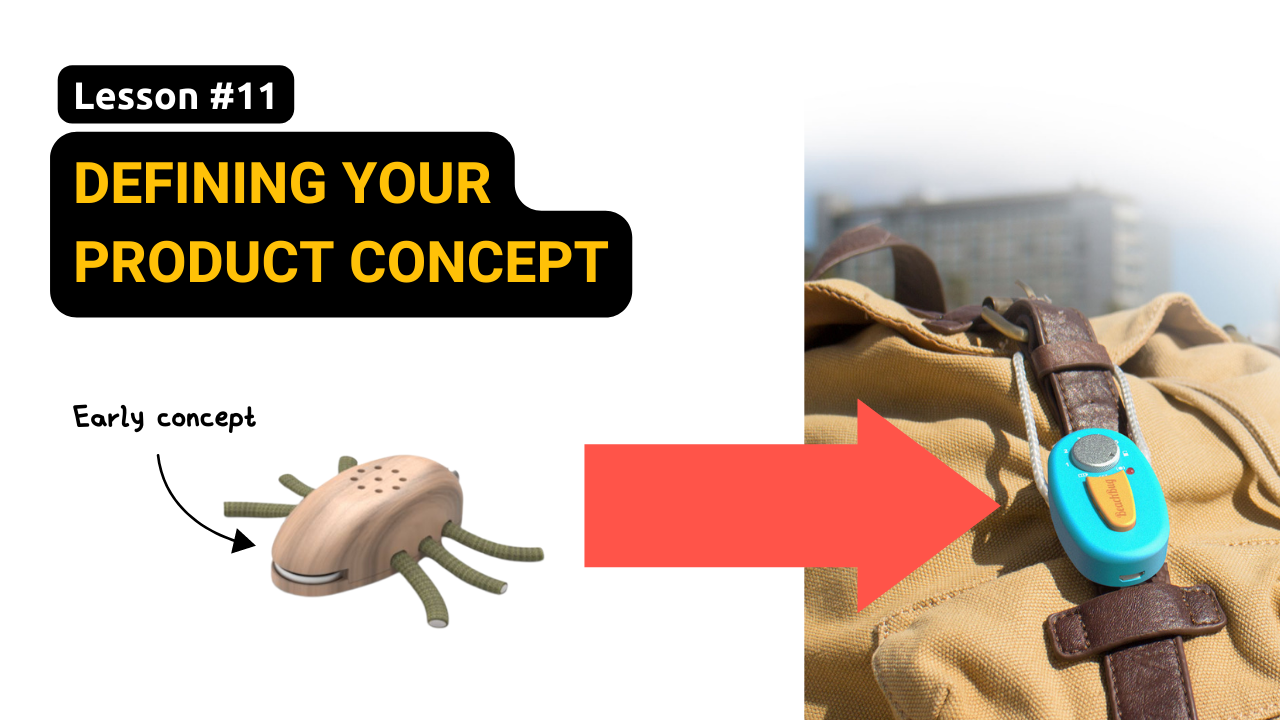

In this video I discuss how to define your product concept so that it is ready for receiving feedback from potential customers.

In this video I discuss how to work with mechanical engineers to have them review your designs and makes sure that they are manufacturable.

In this lesson I discuss some best practices for working with industrial designers. You can watch the lesson here:

In this post we will go over the benefits and the downsides of designing with sheet metal. We will also provide some inspiring examples of creative uses.

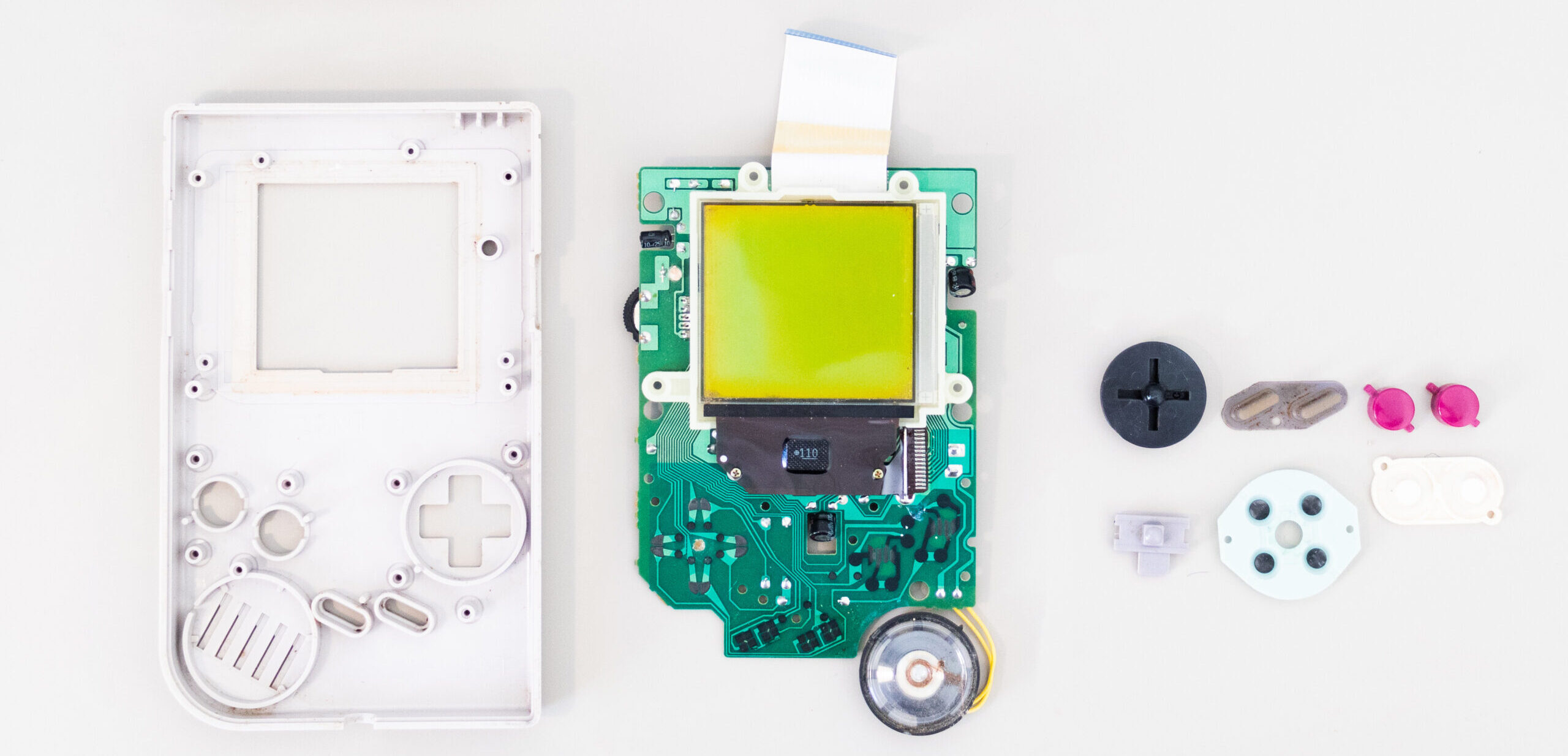

In this post I disassemble the original Game Boy to investigate how it was manufactured.