The use of sheet metal is widespread in product design: automotive bodywork, enclosures, kitchen utensils, the list goes on.

In this post we will go over the benefits and the downsides of sheet metal design. We will also provide some inspiring examples of creative uses.

A short introduction to sheet metal

The rule of thumb is that any metallic stock material thinner than 6mm falls under the category of sheet metal. Common materials for sheet metal include steel, aluminum and brass.

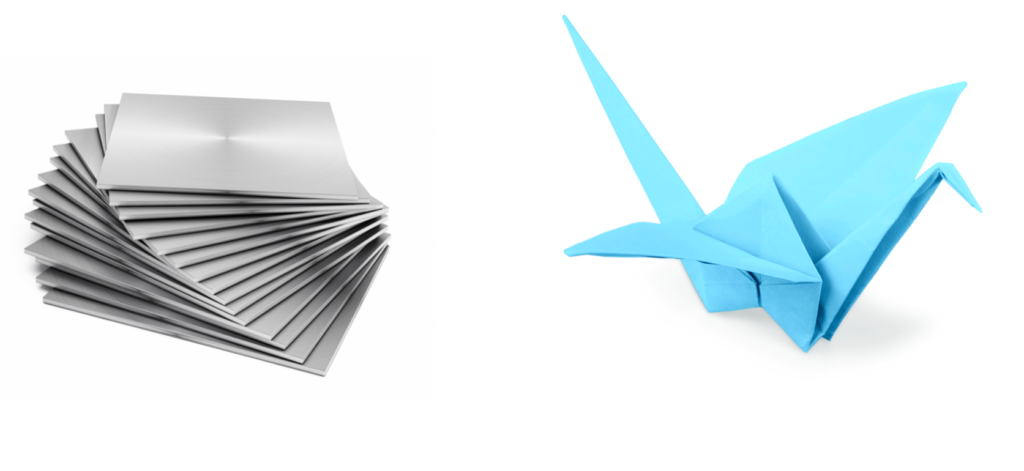

If you are just starting to think about sheet metal design, one useful framing is that it is like origami, but with metal.

Owing to its characteristic shape, sheet metal has advantages and disadvantages when it comes to product design and manufacturing.

Benefits of using sheet metal in your designs

Sheet metal has an ample list of benefits which have contributed to it becoming one of the most common manufacturing methods out there.

Flexibility in Design: A central benefit to sheet metal work is the ability to create widely different designs through simple cutting and deformation operations. We will investigate some examples of creative uses of sheet metal further ahead.

Low Cost: Designs utilizing sheet metal usually require little tooling, which makes the startup cost relatively low. The per-part cost is also normally low since large and strong geometries can be created in few and simple operations. Furthermore, efficient positioning of parts during the cutting phase can make the material wastage low.

Manufacturability: There exists a multitude of ways of altering the shape of sheet metal. There is laser-cutting and punching; bending and drawing; and spinning and electromagnetic forming. This gives designers a lot of freedom to optimize functionality and aesthetics.

Strong and Lightweight: Sheet metal is often a perfect choice for application where you need a lot of mechanical strength at a low weight. An airplane wing is a good example as it sustains an immense load, resists impacts and extreme temperatures. Yet it consists mainly out of thin sheets of aluminum.

Cons of using sheet metal in your designs

While there are significant advantages to sheet metal, it is not always the best way to go.

Not Every Product is Slim: One limitation with sheet metal is that it is useless for products that requires a certain thickness to function. For example you cannot make a heavy-duty machine solely out of thin metal sheets.

Manufacturing Limitations: While the versatility of manufacturing methods was discussed above, there is an equal number of limitations to consider. For example, when bent, sheets will always have a rounding at the bend seam. To achieve a perfectly sharp corner, another manufacturing method would need to be used.

Innovative sheet metal products

Here are a few designs that perfectly illustrate how sheet metal can be used creatively in product development.

B&O A1 Speaker

This minimal speaker by Bang & Olufsen makes intelligent use of sheet metal for its speaker grill. The sheet on the top has a pattern of holes, which fulfills the function of letting sound out while maintaining a minimal aesthetic.

Manufacturing-wise, it has gone through only two main operations. The holes were first cut out and then it was stamped into the final shape.

Service Table by Marcus Hofbauer

I believe even the untrained eye can see that the service table above is dead simple to manufacture. You take a sheet, cut the required shape, and then bend it six times.

Despite that, the table has a lot of functionality such as handles, a wine bottle compartment, and even a place to hold journals. Talk about achieving a lot with little.

The FCTNDSGN Bookend

These bookends are likewise fabricated from one metal sheet. After the cutting operation they have been bent into a corrugated pattern, and then powder coated in paint, completing their design.

Functionality wise they can hold books on a bookshelf, and also work as a book support when reading.

Concluding remarks

As an industrial designer, I believe that being able to design with sheet metal expands one’s creative horizons for creating mass manufacturable products.

I hope this post has illuminated some of the possibilities that sheet metal design provides, and that you will keep it in mind next time you are working.